When browsing the supermarket aisle for edible oil, you’ll likely notice two main types of packaging: plastic bottles and glass containers. While both are widely used, there is a growing preference among consumers and producers alike for glass. This article explores the key differences between plastic and Glass packaging for edible oil and examines the practical, health, and environmental reasons behind the rising popularity of glass.

Table of Contents

Glass Containers: Better Material for Keeping Oil Fresh

Glass stays neutral against oils. Plastic can release compounds into your oil over time, but glass has zero chemical reaction. Your oil tastes just like the producer made it. Three weeks or three months on your shelf – no difference.

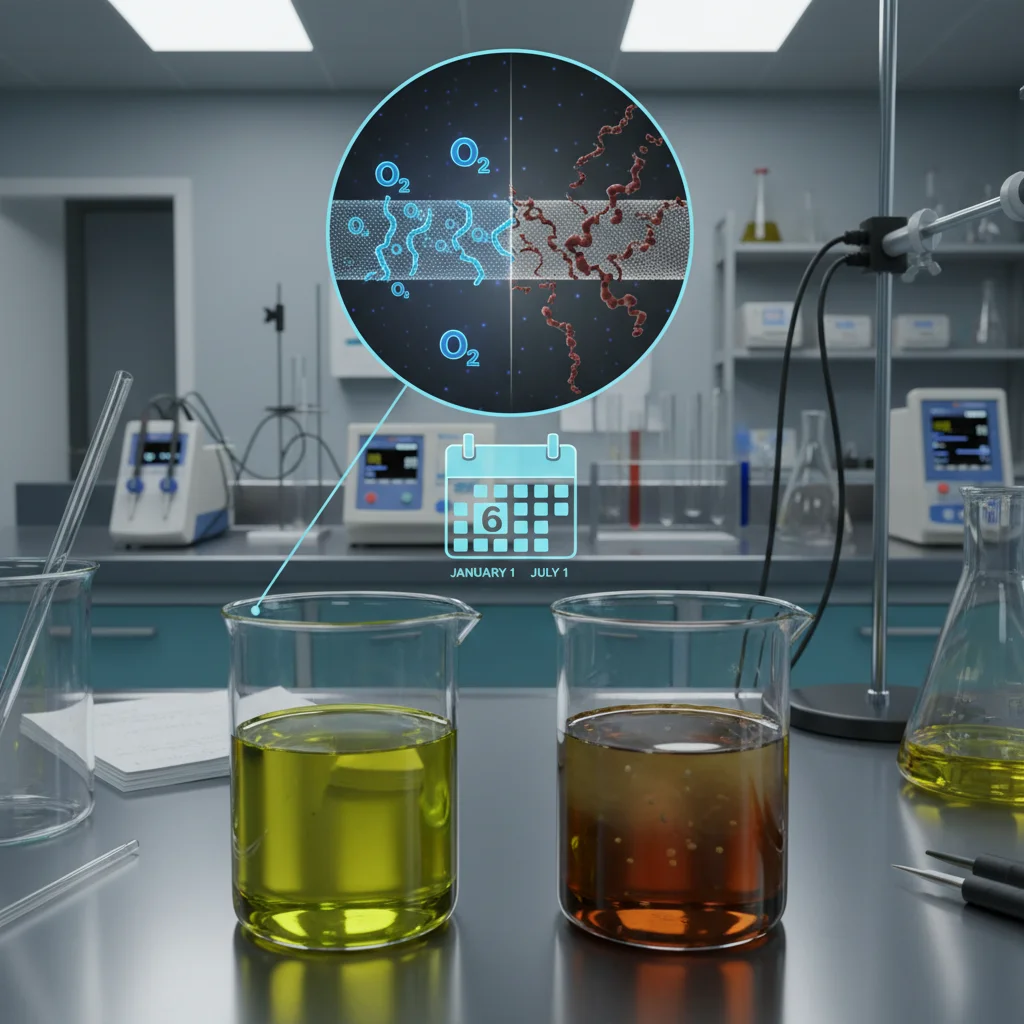

Glass creates a tight barrier. Plastic can’t match this. Studies show glass containers block 100% of oxygen. Plastic containers let oxygen seep through. Even the high-density types have this problem.

Oxygen is the enemy here. It triggers oxidation. Fresh oil turns rancid. Every oxygen molecule that gets through plastic breaks down the fatty acids you paid for.

Light Protection Through Colored Glass

Amber and dark green glass bottles block harmful light. UV rays in the 280-315nm range damage oil stability the most. Dark amber glass blocks 98% of these rays. Standard green glass stops about 85% of UV light. Clear glass helps some, but colored glass creates a real shield.

UV blocking slows down oxidation. Research shows this clearly. Oils in amber glass versus clear plastic? Oxidation markers appear 60-70% slower in dark glass. Your extra virgin olive oil keeps that peppery, fresh-picked taste much longer.

Temperature Resilience

Glass handles temperature changes. Plastic can’t take the same stress. Standard borosilicate glass stays stable from -40°C to 500°C. Regular soda-lime glass in most oil bottles handles -20°C to 200°C. No structural change at all.

Plastic containers start softening at 60°C. They may leach chemicals too. Put a plastic oil bottle near your stove? You’re asking for trouble. Direct sunlight through a window? Same problem. The plastic doesn’t need to melt. Changes happen at the molecular level. You won’t see physical warping right away.

Glass gives you flexibility. Cool pantries work fine. Warmer kitchen areas? No problem. The container won’t break down and affect what’s inside.

Plastic Containers: Chemical Leaching and Oil Quality Problems

Plastic bottles seem convenient. Then you learn what happens inside them. PET and HDPE containers release chemicals into your cooking oil. These aren’t tiny amounts you can ignore.

Lab tests find specific chemicals that leak out. PET containers release acetaldehyde at 2-15 parts per billion in the first month. This chemical adds a sweet, fruity taste to your oil. Something tastes off, even if you can’t pinpoint it right away.

HDPE containers cause different issues. They release oligomers – tiny plastic pieces – into oil over time. Studies show BHT and other additives leak from HDPE walls. These chemicals get into your cooking oil at 0.5-2 mg per kilogram after three months of storage.

The Flavor Theft Problem

Here’s what most people miss: plastic doesn’t just add bad chemicals – it steals the good ones. Food scientists call this “flavor scalping.” Plastic walls absorb the aromatic compounds from your oil.

Think about that pricey basil-infused olive oil. Or that toasted sesame oil from the specialty shop. Those compounds that create the smell? Plastic containers absorb them.

Studies show big losses. PET containers strip away 15-30% of aromatic compounds in six weeks. The lighter flavor molecules vanish first. Your oil turns flat. Dull. Tasteless.

Glass containers stop this absorption. The aroma stays the same. Day one smells like month six.

Faster Rancidity

Plastic lets oxygen through. This creates ongoing damage. Tests show HDPE containers produce peroxide values 40-55% higher than glass after eight weeks at room temperature.

Check the oxygen transmission rates. HDPE lets through 100-300 cm³ of oxygen per square meter daily. PET does better at 50-150 cm³, but that’s still a lot. Glass? Zero.

More oxygen means rancid oil faster. Those healthy fats break down into harmful compounds. The nutrition you paid for degrades while the oil sits in plastic.

Scientific Evidence: Dark Glass Delivers Longest Shelf Life

Lab tests show what happens to edible oils in different containers over time. Researchers tracked olive oil for six months in various containers. Storage conditions stayed the same. The results? Not even close.

Dark glass containers kept peroxide values at 11.41 meq O₂/kg after six months. Polyethylene containers hit 25.40 meq O₂/kg – more than double the oxidation. Clear glass fell in the middle at 18.73 meq O₂/kg. Peroxide values above 20 make your oil taste rancid. You also lose health benefits.

The chemistry is simple. Dark amber glass blocks the 280-400nm wavelength range. This is where oil breaks down fastest from light. Clear containers can’t stop these harmful wavelengths. Oil molecules break down.

Antioxidant Preservation Rates Show Clear Winners

Track the good compounds in your oil. This tells the real story. Phenolic compounds give extra virgin olive oil its peppery bite. They provide health benefits too. Dark glass containers kept 82% of initial phenol content after 180 days. Plastic containers? Just 54% remained.

Chlorophyll breaks down in a similar way. These pigments create that beautiful green color in fresh oils. But they do more. In light, they speed up oxidation. In darkness, they protect oil. Dark glass saved 76% of chlorophyll content. Clear plastic containers? Only 41%.

Tocopherols – your vitamin E compounds – dropped to 69% in plastic. Dark glass kept 89% intact during the same period. Each percentage point lost means less protection for your body.

Professional Tasters Detect The Difference

Certified olive oil experts rated oils from different containers after 120 days. Their taste buds don’t lie. Oils stored in dark glass scored 8.2/10 for quality. The same oil batch in plastic containers averaged 5.8/10.

Experts described plastic-stored oils as “flat,” “musty,” and “lacking complexity.” Dark glass samples kept terms like “fruity,” “fresh-cut grass,” and “peppery finish.” These are the markers of quality oil.

Aroma intensity dropped in plastic. Taste panels found 40% lower volatile compounds in plastic-stored samples. Your nose catches this decline first. Your taste buds notice it later.

Container Performance Across Oil Varieties

Different oils have different storage needs. Extra virgin olive oil showed the biggest differences between containers. It has high polyphenol content. The flavor profile is delicate. Sunflower oil has fewer phenolic compounds. Still, it oxidized 65% faster in plastic versus dark glass.

Coconut oil is interesting. It has high saturated fat content. This makes it more stable. Yet coconut oil developed off-flavors 45% faster in clear plastic. Dark glass containers protected it better. The lauric acid chains still suffered damage from light and oxygen.

These aren’t just lab experiments. Real oils in real kitchens follow these same patterns. Glass containers for edible oil beat plastic across every oil type tested.

Consumer Perception: Why Premium Brands Choose Glass

Premium olive oil brands know something vital about their customers. People judge quality before tasting the product. The bottle speaks first.

Market research shows clear patterns. 73% of consumers link glass packaging with higher product quality compared to just 41% for plastic containers. This perception gap affects buying decisions. Shoppers see two similar oils side by side? The Glass Bottle wins 68% of the time – even when priced 15-20% higher.

Brand case studies tell the real story. Cobram Estate switched their premium olive oil line from plastic to dark Glass bottles in 2019. Their sales jumped 34% within six months. Customer complaints about oil quality dropped by 47%. The product inside stayed the same. The container changed, that’s all.

La Tourangelle made a similar move with their artisan nut oils. They shifted from clear plastic to amber glass for their walnut and hazelnut oils. Their repeat purchase rate climbed from 52% to 71%. Customers reported the oils “tasted fresher” and “lasted longer.” The glass containers for edible oil created this shift in how people experienced and viewed the product.

Retail Shelf Psychology

Walk through any specialty food store. Glass bottles catch light in a unique way. They feel substantial in your hand. This matters more than most brands realize.

Eye-tracking studies in retail settings show interesting results. Shoppers spend 3.2 seconds longer looking at glass-packaged oils versus plastic. Those extra seconds lead to higher conversion rates. Glass bottles convert browsers into buyers at 22% versus 14% for plastic alternatives.

Sustainability drives younger consumers hard. Recent surveys show 81% of millennials and Gen Z shoppers look for recyclable packaging. Glass fits their values well. You can recycle it endlessly without quality loss. Plastic degrades with each recycling cycle – most people know this now.

Practical Tips: Which Container to Use

Not all oils need the same protection. Match your storage choice to the oil’s value, how fast you use it, and where you buy it.

Cold-pressed and organic oils need glass containers. These products cost more because producers extract them with care. Small batches. No heat damage. All those delicate compounds stay intact during production. Then what? You put them in plastic and watch those benefits disappear? That defeats the purpose.

Specialty stores stock these premium oils in dark glass for good reason. A 500ml bottle of organic cold-pressed walnut oil runs £18-25 in the UK. The same volume of standard walnut oil in plastic costs £8-12. That price gap reflects quality. Glass preserves what you paid for. Artisan producers get this. They pick amber or dark green glass bottles. Their oils sit on specialty store shelves for weeks, sometimes months. Glass keeps them stable.

Plastic Makes Sense in Some Cases

Large-format commercial packaging works in a different way. Restaurant kitchens and food manufacturers buy 5-10 liter containers. They empty these bottles within days, sometimes hours. High turnover changes things. A busy kitchen goes through three liters of vegetable oil each day. Oxidation doesn’t have time to build up. Weight matters here too. A 10-liter glass bottle weighs much more than HDPE. Shipping costs go up. Breakage risk climbs.

Budget markets use plastic for basic cooking oils. A family buying refined sunflower oil for frying looks at price first. That 2-liter plastic bottle at £3.50 meets their needs. They’ll finish it in two weeks. Glass wouldn’t boost their experience enough to justify higher costs.

Short-term storage favors plastic’s lighter weight and strength. Catering events. Outdoor markets. Food trucks. These settings need containers that won’t shatter. A dropped glass bottle creates mess and safety hazards. HDPE takes rough treatment better.

Conclusion

Plastic or glass for your edible oil? This isn’t about looks. It’s about keeping your oil’s nutrition and flavor intact. Plastic containers are cheap and easy to handle. But science proves glass containers for edible oil protect better. They block chemical leaks, light damage, and quality loss. Dark amber or green glass works best. It extends shelf life by up to 40% more than plastic.

As a specialized TP Glass Bottle Manufacturer, we are committed to producing high-quality, aesthetically pleasing glass containers that safeguard your oil’s integrity and enhance your brand’s image. Let us help you make the clear choice for your product. contact us today to explore our customizable and sustainable glass packaging solutions.