The right wine bottle manufacturer can make or break your bulk order success. Europe’s glass industry combines old-world craft with modern production power. But finding the right supplier takes some work. You might run a small vineyard that wants elegant custom bottles. Or maybe you’re a distributor who needs millions of standard bottles. Either way, your manufacturer choice affects your timeline, costs, and how your brand looks on the shelf.

This guide covers their specialties, minimum order amounts, and customization options. You’ll see what makes each manufacturer stand out in today’s competitive market.

Verallia (France)

Verallia makes over 16 billion Glass bottles each year. They run 32 plants across 11 countries. Their French facilities handle some of Europe’s toughest Custom wine bottle projects.

Customization Capabilities

Their mold design team works with wineries on bottle shapes. You get access to advanced decoration methods – screen printing, acid etching, hot stamping, and embossing. These methods create unique bottles. They stand out on store shelves. The company works with different order sizes. Small vineyards can order custom designs starting at 10,000 bottles. Large distributors can get millions of standard bottles. Quality stays the same across all production runs.

wine Industry Expertise

Premium wine bottles make up 40% of Verallia’s work. They provide bottles to top French châteaux in Bordeaux and Burgundy. This shows in their design skills. They understand weight balance, punt depth, and shoulder angles that serious winemakers need. Their lab tests new bottle ideas each year. Recent work includes lightweight bottles that cut shipping costs by 20%. Strength stays the same. They also created a special glass formula. It boosts UV protection for wines that are sensitive to light.

Stoelzle Glass Group (Austria)

Stoelzle has shaped Austria’s glass industry since 1805. Their Köflach facility makes top-quality wine bottles for European markets. The company works with mid-sized wineries. These wineries want unique designs but don’t need huge order amounts.

Custom Mold Services

Private mold development makes Stoelzle different from bigger makers. You can create unique bottle shapes. Competitors can’t copy them. Their design team turns sketches into ready-to-use molds in 8-12 weeks. Minimum orders for private molds start at 50,000 bottles. That’s lower than most French makers.

Surface treatment options include organic coatings and frosted finishes. Their color range goes beyond standard green and amber. You can pick custom colors – from deep burgundy to rose gold metallics. Each color batch matches your exact needs.

Wine Bottle Specialization

Austrian and German wineries make up their main client base. Stoelzle designed the slim bottles for Grüner Veltliner wines. These bottles became a standard across Central Europe. Their Bordeaux-style bottles have strong bases. This handles pressure from quality red wines during aging.

The company works with family-owned estates. Some partnerships go back three generations. They know what each region needs. Riesling makers get lighter glass. This keeps delicate aromas intact. Full-bodied red wine makers get heavier bottles with deeper punts.

Vetropack (Switzerland)

Vetropack operates three production sites across Switzerland. They make over 3 billion bottles each year. The facilities in St-Prex, Bülach, and Pöchlarn produce premium and mid-range bottles. Central European wineries rely on their supply.

Automated Production Excellence

Vetropack runs 12 furnaces at full capacity. Each line produces 400 bottles per minute. Automation reduces human error. Quality stays consistent across large orders. Their Industry 4.0 technology monitors quality in real time. Defective bottles get pulled before packing.

The company keeps popular wine bottle styles in stock. Standard Bordeaux and Burgundy shapes ship in 2-3 weeks. Custom orders need 10-12 weeks after design approval. You can order custom molds starting at 25,000 bottles. That’s doable for growing wine brands.

Sustainability Leadership

Vetropack uses 60% recycled glass. The European industry average sits at 52%. Two facilities run furnaces on renewable energy. They’re aiming for full carbon neutrality by 2030. Each bottle weighs 15-20% less than traditional designs. Lighter glass cuts shipping costs for bulk orders. Testing proves these bottles handle the same pressure as heavier ones. Their “Eco-Light” bottle line appeals to eco-conscious wineries. These bottles use less material. Protection stays strong. German and Swiss organic wineries started using this line in 2021. Adoption has been quick.

Ardagh Group (Ireland/Multi-country)

Ardagh operates 57 glass plants across 12 countries. This global reach helps them handle big wine bottle orders fast. Plants spread across Ireland, Germany, France, Italy, and Poland. Quality stays the same no matter which plant fills your order.

Cross-Border Production Management

Large distributors save money with Ardagh’s multi-country setup. Need 5 million bottles across Europe? They split production between plants. German facilities ship to Central Europe. French plants handle Mediterranean orders. You cut logistics costs by 25-30% compared to single-site suppliers. Their tracking system monitors orders across all plants. One account manager runs your entire European supply. Each site follows the same production rules. A Bordeaux bottle from Dublin matches the one from Italy exactly.

Standard and Custom Product Mix

Stock bottles make up 70% of what Ardagh produces. They stock 40+ popular designs ready to go. Burgundy, Bordeaux, Alsace, and Riesling shapes ship right away. Stock orders start at just 2 pallets – about 2,400 bottles. Custom work runs differently. Design centers in Italy and France build premium molds. Custom projects need 100,000 bottles minimum. That’s more than small makers require. You get advanced decoration options though – ceramic labels, metallic finishes, and layered embossing.

Wiegand-Glas (Germany)

Germany has a rich glass-making history. Wiegand-Glas carries this tradition forward. They run five plants across the country. Small and medium wineries? They get real attention here. Big makers often skip flexible custom orders. Wiegand-Glas built its name on exactly that.

Low-Volume Custom Orders

Most European glass plants demand 100,000+ bottles per custom run. Wiegand-Glas starts at just 15,000 bottles. Your small winery can get unique bottle shapes. No massive upfront costs needed. They handle sample work in-house. You’ll see physical prototypes in 3-4 weeks. No months-long wait.

Their fast tooling process saves 40% on mold development time. Standard makers take 16 weeks. Wiegand delivers working molds in 9-10 weeks. Small wine producers launching new lines? This saves key time during harvest planning.

EU Distribution Network

Five German plants put bottles closer to your cellar. They have sites in Bavaria, Hesse, and North Rhine-Westphalia. These spots cover major wine areas. Their warehouses stock popular bottle designs. Orders under 5,000 bottles? They ship from ready stock.

Delivery beats competitors across the EU. German wineries get stock bottles in 5-7 days. French and Italian customers receive shipments in 10-12 days. They work with local freight services. On-time delivery hits 94% – based on 2023 orders.

Harvest season rush orders get priority treatment. They save production space for urgent needs from September through November.

BA Glass (Germany)

BA Glass stands apart in the German glass industry. Most makers push automation and mass production. BA Glass kept hand-blown bottle making alive. Their craftsmen create Custom Wine Bottles that machines can’t copy.

Hand-Blown Craftsmanship

Hand glassblowing shapes every bottle at BA Glass. Master craftsmen with 15-20 years of practice work the furnaces. They blow hot glass into unique forms. Each bottle shows small changes that prove human hands made it.

This matters for luxury wine brands. Collectors spot the gap between machine uniformity and artisan style. Hand-blown bottles have thicker glass at stress points. Air bubbles create natural patterns inside the walls. These details show exclusivity.

You get design freedom that standard molds can’t offer. Asymmetric shapes? Done. Unusual neck angles? No problem. BA Glass made a small series of bottles with built-in glass stoppers for a Rheingau estate. The stopper and bottle came from one piece of glass. Try getting that from automated lines.

Artistic Bottle Design

BA Glass has in-house designers who get wine bottle looks. They sketch ideas based on your brand story. A Black Forest winery wanted bottles that looked like pine trees. BA Glass made tall, slim bottles with textured glass that copied bark patterns.

Color work goes beyond standard amber and green. Their furnaces make custom glass batches in specific shades. Sunset orange for a rosé wine. Deep cobalt blue for an ice wine set. Minimum color runs start at 2,000 bottles. That’s rare for custom colors.

Embossing and relief work gets done by hand. Craftsmen carve patterns into cooling glass. No extra embossing step needed. The result shows sharper detail and deeper depth than machine embossing.

Small Batch Production Advantage

Order minimums drop to just 1,000 bottles for hand-blown work. Small wineries making limited vintage runs now have options. You don’t need to commit to 50,000 bottles just to get something unique. Small edition releases suit BA Glass well. A Mosel winery ordered 500 magnums for their anniversary vintage. BA Glass hand-blew each bottle with the estate crest in the glass. Production finished in six weeks. Quick work for full custom bottles.

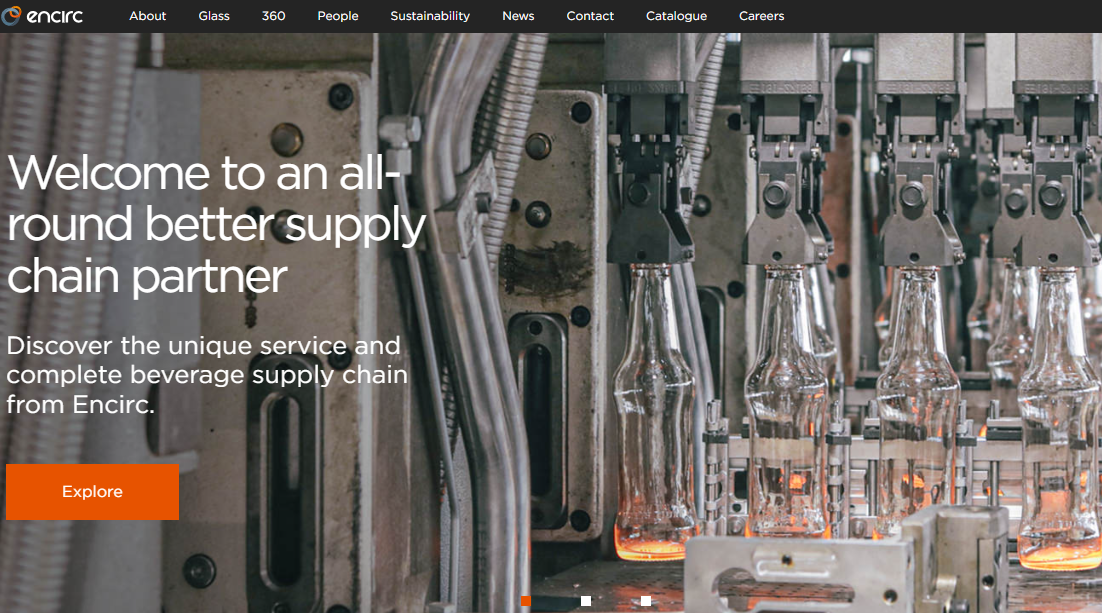

Encirc (UK/Ireland)

Encirc runs one of Europe’s top glass recycling systems. Their Derrylin facility in Northern Ireland processes 400,000 tons of recycled glass each year. This glass goes straight into making new bottles. The closed-loop system cuts raw material costs by 35% compared to standard glassmaking.

Lightweight Innovation

Encirc focuses on making lighter bottles. Their Ultra-Lightweight range brings standard 750ml bottles down to 320 grams. Standard wine bottles weigh 450-500 grams. You save 28-36% on shipping costs per container. A full truck carries 15% more bottles with this lighter design.

These bottles pass tough strength tests. They handle 90 PSI internal pressure. That beats what still wines need. Sparkling wine producers get stronger versions at 380 grams. These still weigh less than most competitors’ standard bottles.

The weight savings grow fast with bulk orders. Ship 1 million bottles? You cut freight costs by £12,000-£15,000 compared to heavier options. Plus, there’s the green benefit. Lighter weight means less carbon release during transport.

High-Speed Automated Production

Twelve furnaces run around the clock at Encirc’s plants. Each line makes 500 bottles per minute. Automated systems scan every bottle. Cameras spot cracks, air bubbles, and size errors. Defect rates stay under 0.3% – top quality control in the industry.

The system handles orders from 50,000 to 5 million bottles. Production shifts with peak harvest times. Stock bottles ship within 10 days. Custom orders take 6-8 weeks.

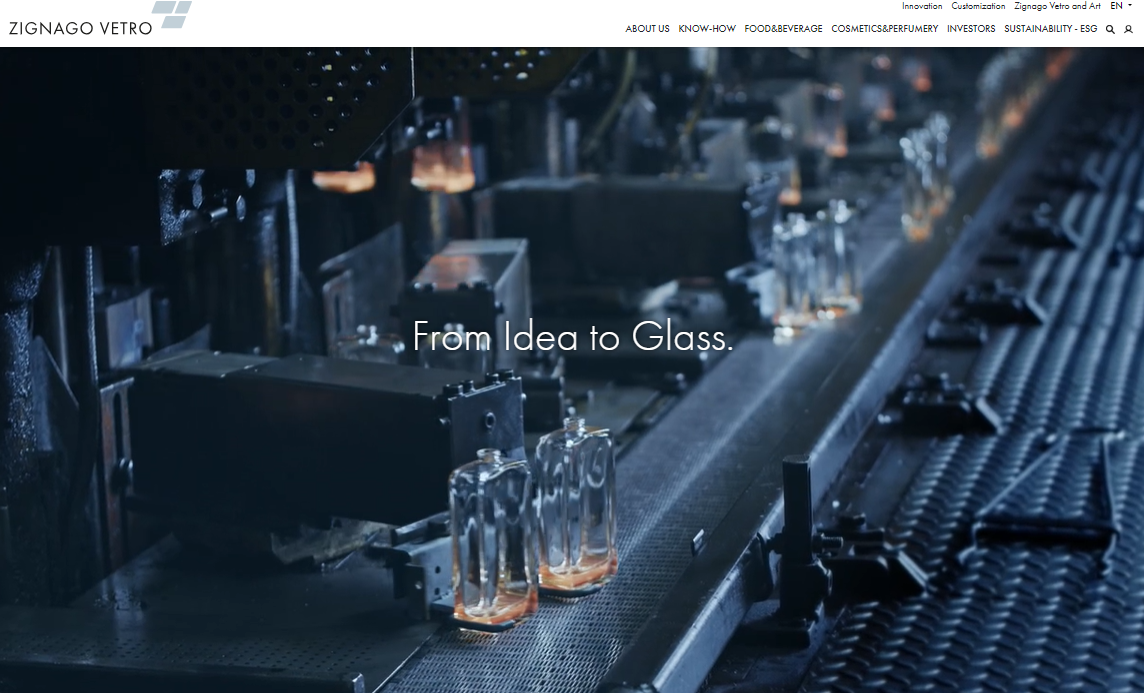

Zignago Vetro (Italy)

Italian glassmaking runs deep in Zignago Vetro’s DNA. The company operates seven plants across Italy and Spain. Mediterranean wineries choose Zignago for premium bottle projects. Tuscany’s Chianti producers use them. So do Spain’s Rioja estates. They get what Southern European wine culture needs.

Mediterranean Market Expertise

Zignago’s Italian facilities sit close to major wine regions. Plants in Veneto and Puglia serve local producers. Travel time drops to 2-3 hours instead of days. Rush orders during harvest? They handle them fast. Spanish operations cover the Iberian Peninsula with the same speed.

The team speaks wine country language. Account managers work in Italian, Spanish, Portuguese, and French. They know what each region wants. Barolo producers get heavy bottles with deep punts. Prosecco makers choose lighter designs that show off the wine’s sparkle. Greek island wineries order custom shapes. These honor ancient amphora styles.

Premium Bottle Specialization

Luxury wine bottles make up 65% of Zignago’s production. Their decoration workshop handles fancy surface treatments. Multi-layer screen printing creates detailed vineyard crests. Hot stamping adds gold or platinum accents to bottle necks. Acid etching makes frosted patterns. These catch light on retail shelves.

Custom mold work starts at 30,000 bottles. This sits between artisan shops and mass producers. Design teams work side-by-side with winemakers. A Sicilian estate wanted bottles shaped like Mount Etna. Zignago delivered prototypes in five weeks. The final design became that winery’s signature look.

Quality-Focused Production

Each bottle goes through manual inspection plus automated scanning. Glassblowers check wall thickness at stress points. Premium wine deserves zero defects. Their rejection rate stays under 0.2% on custom orders.

Standard lead times run 8-10 weeks for custom projects. Stock bottles from their catalog ship in 3-4 weeks across Southern Europe.

Conclusion

The right wine bottle manufacturer for your bulk orders affects your brand’s market presence and production efficiency. Europe’s glass manufacturing gives you exceptional variety. Your ideal partner depends on three key factors: order volume, customization needs, and sustainability goals.

Ready to move forward? At TP Glass Bottle Manufacturer, we combine European craftsmanship with a client-focused approach to deliver exceptional Custom glass bottles at competitive bulk rates. Whether you seek elegant traditional designs or innovative modern shapes, we ensure precision, quality, and timely delivery—helping your brand stand out in every detail. Let’s bottle your vision together. contact us today to discuss your next project.